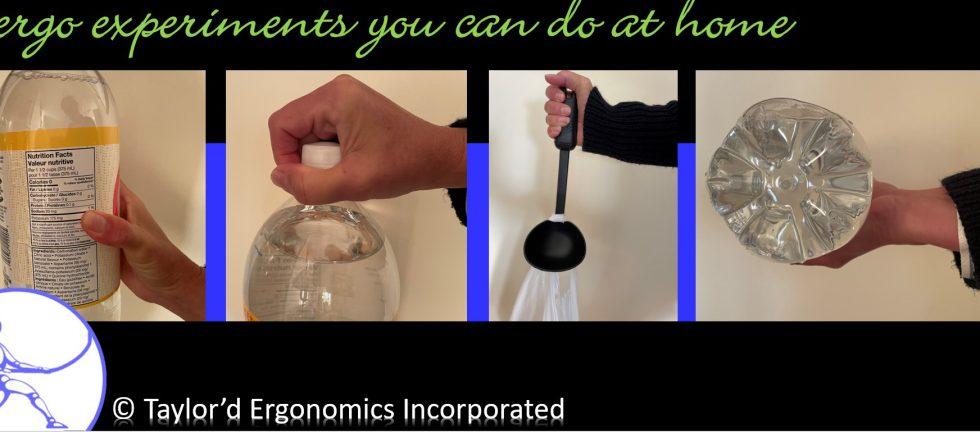

Ergonomics experiments you can do at home

A few months ago, I reported about how “glove fit” affects grip strength. (Better fit = greater strength). This morning, I played around with grip endurance using different types of grips, and performed a little experiment at home. Here’s what I did: I found a 2-litre bottle of liquid (about 2 kg). I opened the […]