Ewwww! I don’t like that metaphor either. But gore aside, workers often find the “best way” to do a task. And ergonomists are sometimes asked to evaluate alternative methods. How do we do this?

We use objective analysis tools to compare methods. Some ergonomists use motion capture tools, which evaluate how much time is spent in various awkward postures. Some people use pen and paper tools like RULA and REBA. If one task requires more bending, or more overhead work, these tools show that the method with more neutral body postures is preferable to the awkward method.

Of course, comparisons are rarely that simple. I would argue that the force, and the direction of force, are as important as the postural loads. (For more, read this: Directionally challenged: When assessing effort, direction matters)

Here are a few technique advantages that would not be “captured” with motion-capture or pen and paper tools:

- Divert the load: A worker pushes forward on a long wrench with the hip, instead of pushing it with the hands.

- Change the grip: A worker carries a 2 kg stack of paper vertically “on” the hand, instead of pinching and gripping the horizontal stack.

- Optimize the direction of push: A worker steps to the end of a roller conveyor to push a carriage forward, instead of standing facing the side of the conveyor and pushing sideways with one arm.

- Test the load, and adjust your grip for better balance: A worker nudges the load with a hand or foot to identify how it is balanced, so the hands can be positioned around the center of gravity.

- Plan the work to minimize effort: A worker packages contoured parts in a large open bin so they nest together perfectly, avoiding the need to squish them all together forcefully to fit the last part in the row.

In the field, ergonomists are often amazed by the tips and tricks that workers develop to minimize the physical demands. An old proverb dictates that “Necessity is the mother of invention.” Ontario workplaces are full of inventors who get little credit for their creative approach to difficult tasks.

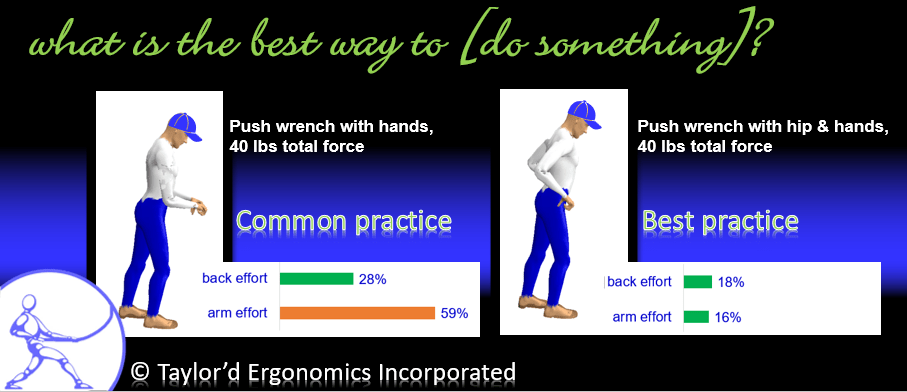

The example I’ve highlighted in the image above shows the demands on the back and arm muscles while pushing on a wrench using the hands (a common practice) and using the hip and hands (a best practice). The postures are so similar that a motion capture comparison likely wouldn’t pick a favourite. However, using the hip to lean into the wrench can reduce the arm effort substantially. This tip doesn’t work in all situations, of course, but wouldn’t you want workers to know about this trick, when it could work?

Why look for the best way?

We rarely give workers a forum for sharing the incredible techniques that they’ve developed. If we identify an experienced worker as a “trainer”, then that worker’s tips might get passed on to new workers, while other co-workers might struggle every day.

Sometimes workers can be a bit secretive about their tips. They may worry that their “trick” is a cheat that circumvents a standard procedure or might not be safe. (If it is unsafe, obviously we don’t want to promote it!) Sometimes they think their tip gives them a special edge; they get to leave for a break 10 seconds earlier and get the best spot in the lunchroom, they have less mess to clean up at the end of the shift, or they receive praise for doing a better job.

If the tip provides a legitimate advantage, we ought to be promoting its use! When we truly listen to workers explain why they do things the way they do, we can invest in their job satisfaction, while helping others to work more comfortably.

We can help! Our ergonomists are trained to collaborate with workers to root out all of the tricks they have found to make their jobs easier. We use our analysis tools to quantify the differences between techniques. We check with your safety folks to ensure that the tip doesn’t introduce a new problem. And we can create posters and coaching plans so trainers and supervisors can encourage people to use the “best practices”.

Studying best practices can prevent injuries, improve employee engagement, improve productivity, and ensure higher-quality outcomes.

Contact me for info@taylordergo.com