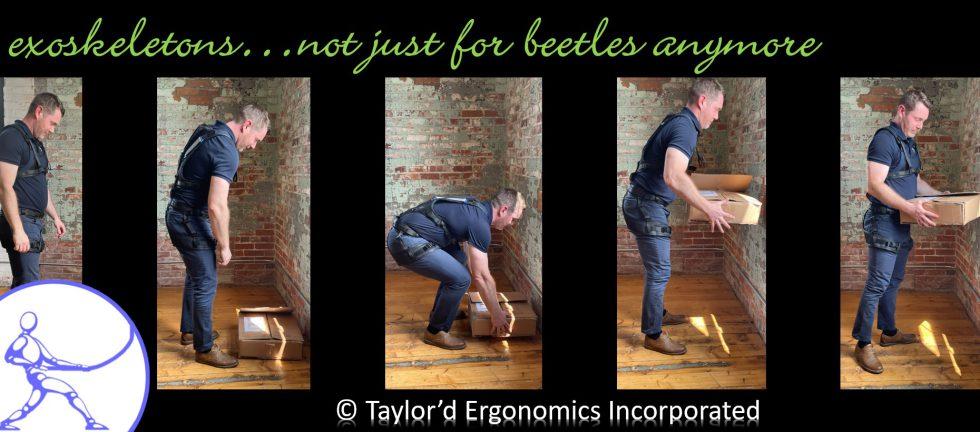

We have acquired a back exoskeleton for trials, and we have been toting it around to our regular clients to see how and where it works best. This particular model is the LiftSuit by Auxivo, and it was generously provided on a trial by DKY Group (www.dky-group.com). The Liftsuit is a “passive” exoskeleton, which means that it uses textile springs (like elastics) to help counter the weight of the torso as the worker bends forward. The load is transferred to the thighs through straps at the legs and shoulders. The photo above shows Alex bending to lift a box while wearing the exoskeleton. Much like the exoskeletons of insects that we learned about in elementary school, these devices offer a certain amount of protection for our soft tissues.

There are many exoskeletons on the market right now – some of them are active, meaning that they use motors, pneumatics, hydraulics, or a combination of technologies to enhance the worker’s power and support the limbs or body. Most of them are a bit bulky; the device sits outside the body, so the more equipment the device involves, the more space it takes. Alex came to Taylor’d Ergo with quite a lot of experience working with active upper limb exoskeletons and he assures us that it’s a mixed bag; they work really well for some people at certain applications, but can be quite intrusive and cumbersome for others.

I (Carrie) was looking for a better way to support a forward-bent posture for a couple of jobs where we have not been able to reduce the forward reach, despite many efforts over the years. In one case, the worker leans against a padded wall, and reaches forward to perform work at a moving conveyor. Most back exoskeletons transfer the load to the thighs using a buckle and strap system, so it was important that this device would not create pressure points on the thighs. The LiftSuit passed this test.

In another work environment, an active arm exoskeleton had been trialed years ago, but was rejected because no one wanted to be seen wearing it; apparently, it just wasn’t “cool” to need support. I hoped that the back exoskeleton would not be as obvious. Without prompting, some of the workers who trialed the LiftSuit in that workplace wore it under their jackets or coveralls….the Liftsuit offered more discretion than the active exos with their rigid materials and electronics.

The most common complaints about the back exo were around heat and fit. The LiftSuit that we trialed was the “version 2”, which incorporated lighter materials with better airflow than its predecessor. It’s hard to imagine what else they could do to make it cooler. The fit issues are tricky; for the device to work, all of the straps need to be snugged up. And there are a lot of straps and buckles! We assured the workers that, if this was their device, they would adjust it once and it would stay “fitted”. But each trial required quite a bit of fiddling to get it adjusted. It is not possible for a worker to adjust all of the straps while wearing the device; help is required. We got better at making the adjustments with practice, but sometimes the leg straps would ride up, sometimes the waist strap looked uncomfortable, the chest strap irritated one person, and occasionally the shoulder straps didn’t sit quite right.

We were provided with a “Large” suit for trial, so we were limited to only large workers. We didn’t have an opportunity to run trials with average or smaller workers and, in fact, when I tried the suit on, it couldn’t do anything for me. It’s quite possible that some of the fit issues were due to the worker not being a good fit for the trial device. It’s quite likely that some fit issues were caused by our inexperience or lack of skill in adjusting the straps properly. (Definitely, the latter trials were more successful than the first few.) In the real world, most exoskeletons will be trialed and used without the benefit of an ergonomist, so if they can’t be put on and adjusted independently, their benefits will be limited.

When we run product trials, we ask workers to fill out a feedback form for us, so we get “measurable” info in addition to their comments. Here is a summary of 6 workers from one facility. (Trials involved a variety of jobs.)

Back discomfort on a typical day (1=extreme discomfort, 10=perfect comfort):

Average 4.3 (range 2-7)

Product rating (1=extremely uncomfortable, 10=amazing):

Average 7.25 (range 6-9)

While 4 of the 6 workers identified something that bugged them about the device, every single one also felt that helped their back. That has to be worth something! Overall, we think the LiftSuit and other exoskeleton devices have enormous potential to improve job demands for tasks that simply cannot be fixed with engineering controls. In the future, we hope to see exoskeletons that:

- Can be donned, doffed (great words for “put on and taken off”) and adjusted easily and without help.

- Don’t increase heat load (Hmm…maybe they could incorporate cooling features….)

- Do not pinch or rub at any body part.

- Are easy to activate or deactivate. For example, workers who lift and then sit for long periods of time would need to unlatch buckles on the current devices.

- Could double as a hi-vis jacket or safety harness.

If you’re interested in running exoskeleton trials in your workplace, please reach out to carrie@taylordergo.com for some help!