by Callum Murphy

Last week, Alex and I participated in an Exoskeleton Conference presented by CRE-MSD. If you’re interested in more details, the slides can be found here: Manual Handling: Where Exoskeletons Fit Within Musculoskeletal Disorder (MSD) Prevention Strategies | Centre of Research Expertise for the Prevention of Musculoskeletal Disorders (CRE-MSD) | University of Waterloo (uwaterloo.ca)

This is a summary of what we learned:

The original ideas and designs for wearable supportive technology (“exoskeletons”) were large and complicated, and were treated like a one-size-fits-all problem solver. Many of the original designs brought Hollywood to mind, evoking images of “Aliens”, “Avatar” and “Ironman”. Recent exoskeletons (I’ll refer to them as “exos” from here on) are simpler and more specialized. Designing them for one specific function has been a big part of their success over the last 10-15 years.

Several kinds of exos are available, specific to the power source, body location, and function:

- Active exos have computer-based controls that learn about the habits and preferences of the wearer.

- Passive exos do not have any motor or power source. They rely on spring tension, dampeners, or other elastic materials to store and release energy to support the wearer.

- Shoulder (or upper body) and back exos are the most prevalent in the research and discussion presented.

User comfort and perception have been major factors in getting workers to wear the units on a voluntary basis, with a notable preference for the comfort offered by soft, passive units.

There were two major areas of debate or discussion between presenters/panelists that I feel are worth noting:

- Where do exoskeletons fit into the hierarchy of controls (i.e engineering, administrative, personal protective equipment, other)?

There were many different opinions on this and a lot of “it depends on how you use them”, but my takeaway was that exos can be considered PPE, but are more accurately described as a wearable device or tool. The research performed on them, while theoretically promising and functional in lab settings, has yet to be conclusively proven to reduce strain/sprain injuries in the field.

- Should exoskeletons be made mandatory when implemented?

The panelists didn’t draw a clear conclusion about this, other than, “It depends on the workplace.” If exos are considered PPE, they will likely be mandatory, because they are protecting workers from a hazard; this means that they must be available to fit all workers. Not all exos are available in all sizes, so this problem must be considered at length. (In our client trials using a passive back exo, very large workers are more likely to tell us that the straps are uncomfortable.) If exos are not mandatory, some workers will decide not to use them. Companies would have to be prepared for an expensive piece of tech to sit around collecting dust. And whatever problem they were intended to solve will remain uncontrolled.

When are they most useful? Research from Toyota suggested that employees performing tasks with long cycles and effort durations (20 min cycle with 120s of overhead work at a time) and fewer times dropping the hands down to retrieve parts saw much more benefit from exo use than the short cycle (1 minute) tasks with short effort duration (less than 10 seconds). This suggests that perhaps, if a job requires the worker to hold the arms up continuously, then the exo would help relieve the load.

Field studies have had less success than lab studies in showing the benefits of exos. Field studies are difficult to do, because life and production tend to get in the way of pesky science. However, these studies are critical for us to understand how actual people will use the tech. One 18-month study saw a 52% reduction in medical visits for exo users, but perceived work intensity and MSD scores were not significantly affected. Effects of an arm-support exoskeleton on perceived work intensity and musculoskeletal discomfort: An 18-month field study in automotive assembly – PubMed (nih.gov)

What are the downsides of using exos? The main two are an increased risk of slips/trips/falls (on lower body or back and hip exos) and the potential for an exo to transfer tool vibration directly to the trunk (with no dampening by the arm) which is very bad for the spine. Increased thermal discomfort (heat stress) is also important, both as an OHS concern and as a factor in getting workers to wear exos.

ASTM is working on a list of guidelines and standards relating to EXO use (WK73074 New Guide for The Application of Ergonomics to Prevent Injuries During Exoskeleton Use (astm.org). Anyone who is researching exoskeletons for their workplace should check this out. You can also get involved on committee F48 (Committee F48 on Exoskeletons and Exosuits (astm.org).

The final panel concluded that combining the right type of exo, the right task, and the right workers are keys to successfully implementing an exo at a job. Exos are not a “fire-and-forget” solution. They need a team of dedicated individuals to support and guide their use.

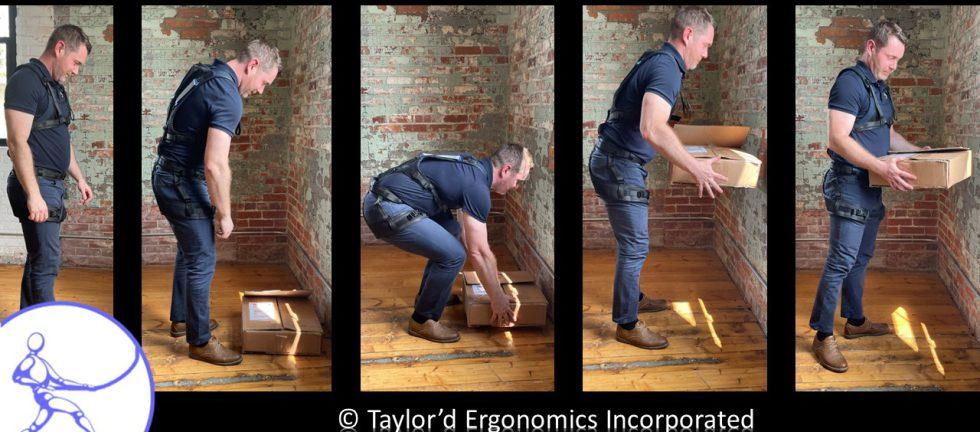

Our team has some experience with exoskeletons, and we’re keen to help our clients explore how they can be used. Please reach out to us if you’re thinking about trialing exoskeletons at your workplace.