This is a story about how our ergonomists helped employees at a brand new line in a light assembly setting. Before we were brought in, several employees had reported discomfort in the back, neck, shoulder, and hand/arm areas. The EH&S Manager (we’ll call her Sonya) asked us to investigate and provide recommendations.

Analysis method

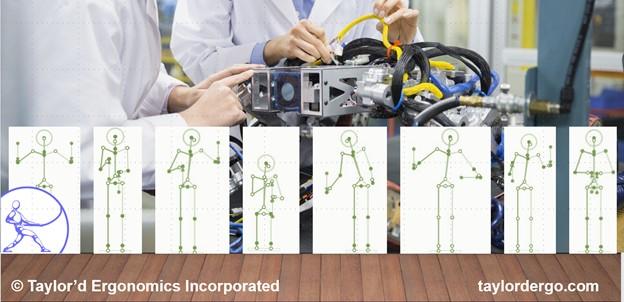

Josie and a novice ergonomist met with Sonya and the project team to ensure that everyone was on the same page regarding the project “question” and the approach we would take. The ergonomists observed each workstation, breaking down all of the tasks, and measuring efforts, hand heights, and reaches. They interviewed the workers to better understand employee concerns and ideas to improve the jobs. They completed biomechanical assessments for each major task at each of the eight stations. Those little stick figures in the image above are from their assessment. They evaluated the risk of injury for each job using the “recommended cumulative recovery allowance” (RCRA) method (Gibson and Potvin, 2016).

The RCRA calculates the amount of muscle recovery time that is needed after each effort; harder efforts take more recovery time. It then tallies up all of the recovery time required, and compares that with the amount of recovery time that is available. If the muscles don’t get enough recovery time, eventually they will fatigue and become susceptible to injury.

Here’s an example you can try in less than 2 minutes, using a stopwatch (or app) and a weight (a book, can of beans, or one of those dumbells collecting dust in the corner). Use the times shown below to follow the exercise with your stopwatch.

0:00 Pick up the weight, reach your hand as far forward as you can, at shoulder height, and hold it there.

0:15 Drop your arm and rest. Does your arm feel a little bit tired? (If not, pick a heavier weight and start again.)

1:15 Reach out with the weight again.

1:30 Drop your arm for a shorter rest period. If a one-minute rest was enough, your arm probably feels about the same as it did after the first effort.

1:40 Reach out with the weight again.

1:55 Drop your arm. If your arm feels more tired this time, a 10-second rest was not enough! Imagine repeating 15-second efforts with only 10-second breaks all day long!

The trick is to allow the right amount of time before repeating the effort, so at the end of the day, you have not built up any discomfort.

“Muscle recovery time” does not mean “coffee break”. In the example above, you could respond to text messages on your phone while you waited for your shoulder muscles to recover. The effort required to work with light loads in neutral postures (no bending or reaching) would be “restful” for your shoulder muscles.

One of the jobs in our case study included one particularly difficult task. The operator placed a 10 lb part on a shelf that was above shoulder height, at a forward reach of about 50 cm (20”). This task was completed once every 72 seconds. Although the task took only a couple of seconds, it was so awkward and heavy that the muscles required about 25 seconds of recovery time. The job also involved manipulating parts on the work bench, and using a drill. The total recovery time needed was about 70 seconds per cycle, but only 28 seconds were available, so the risk index worked out to 2.5. (Anything higher than 1 warrants improvement.) A couple of other jobs also had high risk for some body parts.

Is job rotation helping?

The the project team naturally wanted to know if job rotation was helping. The ergonomists combined all the jobs together into one RCRA assessment. The rotation as a whole presented a high risk (risk index >1) for only the left shoulder.

The ergonomists met with Sonya, the supervisor and the manager, to review the analysis results. Josie facilitated a brainstorming session, getting everyone involved in identifying potential solutions for high risk tasks.

The ergonomists then crunched some more numbers to evaluate these potential solutions recommendations, alone and in combination. These “what if” assessments helped to prioritize interventions. They answer the question, “What needs to be changed to bring the rotation risk index below 1?”

Not all ergonomists use technical tools such as biomechanics software and the RCRA assessment. However, the sensitivity of these tools helped us to focus on specific hazards, and predict how changes would reduce the risk. The approach also helped to show that job rotation could help to reduce risk.

Feedback from the EH&S Manager:

“I wanted to email you and thank you for your help with this ergo assessment project. We set up a meeting earlier in the week with the ergonomists and our management team (including the Plant Manager) to review the format of the ergo assessment, and focus on the high risks found. The meeting was great, the team was engaged, we had good brainstorming-type discussions and the team is very pleased with the work completed by the ergonomists.”